Inspection Equipment Market for Electronics Industry Set to Grow at 4.07% CAGR, Reaching USD 2.7 Billion by 2035 | Exclusive Report by TMR

The global inspection equipment market for the electronics industry is poised for robust expansion, driven by the increasing complexity of electronic components and heightened quality assurance demands. Technological advancements in automated inspection systems are set to transform quality control processes across the sector.

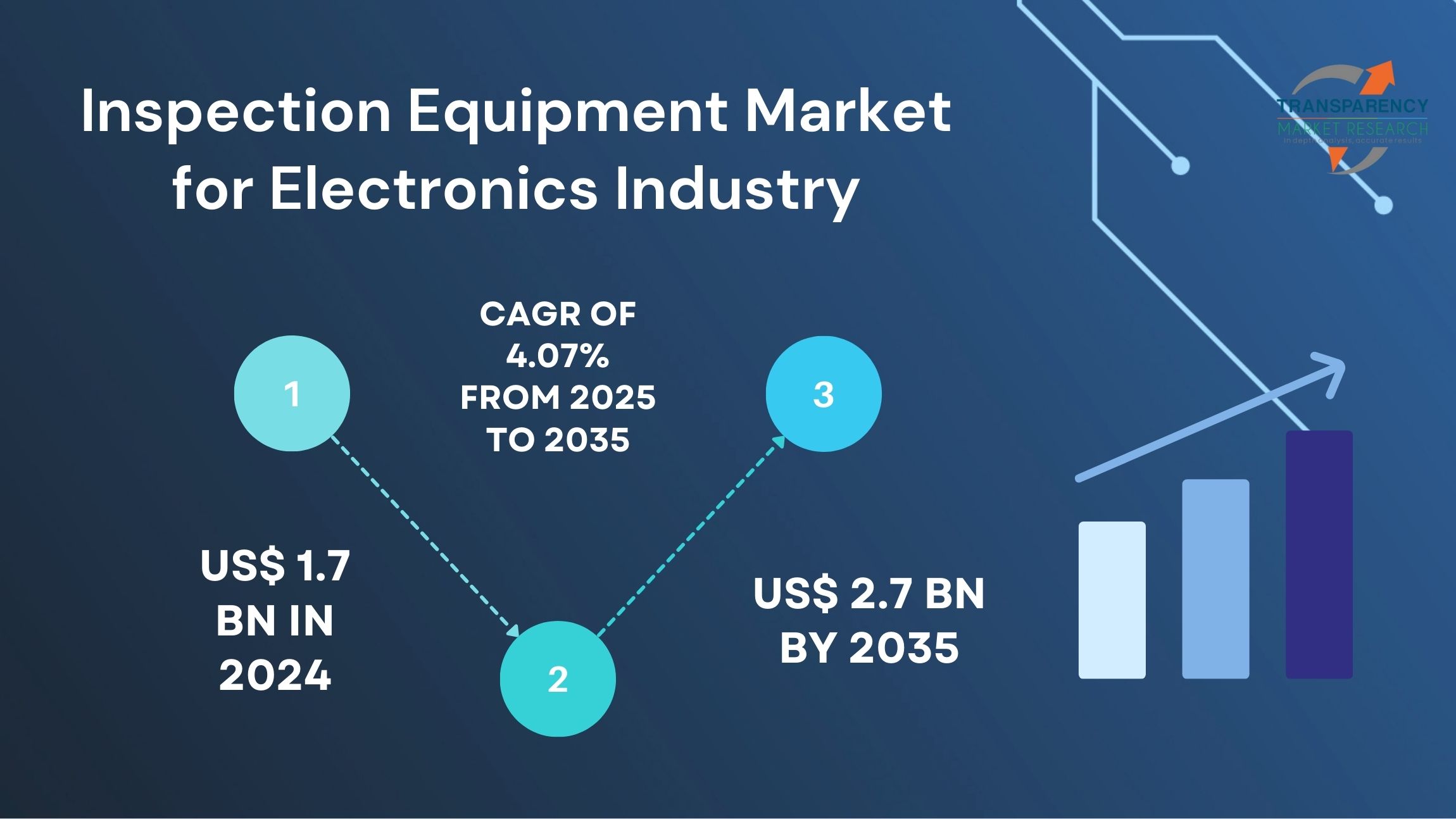

/EIN News/ -- Wilmington, Delaware, Transparency Market Research Inc. – , Feb. 25, 2025 (GLOBE NEWSWIRE) -- The global inspection equipment market for the electronics industry, valued at USD 1.7 billion in 2024, is projected to advance at a compound annual growth rate (CAGR) of 4.07% from 2025 to 2035, ultimately reaching USD 2.7 billion by the end of 2035.

This growth is propelled by the escalating complexity of electronic components, the demand for superior quality assurance, and the integration of cutting-edge technologies such as Automated Optical Inspection (AOI), X-Ray inspection, and 3D inspection systems.

Request exclusive data and projections—get your market report sample from here: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86460

Analysts’ Viewpoint

The electronics industry’s inspection equipment market exhibits tremendous potential as manufacturers grapple with the challenges of miniaturization, sophisticated component integration, and rising customer expectations.

Advanced inspection technologies not only enhance defect detection and ensure compliance with stringent regulatory standards but also boost productivity and reduce production costs. The incorporation of Industry 4.0 elements—including artificial intelligence and data analytics—is revolutionizing the inspection landscape, enabling real-time quality tracking and proactive decision-making.

Market Overview

The Inspection Equipment Market for the Electronics Industry is witnessing significant growth, driven by the increasing need for high-precision quality control, miniaturization of electronic components, and advancements in semiconductor manufacturing. With the rise of smart devices, electric vehicles (EVs), 5G infrastructure, and IoT-enabled electronics, manufacturers are investing heavily in automated and AI-powered inspection technologies to enhance production efficiency and defect detection.

The market is expected to grow at a strong CAGR, fueled by the adoption of machine vision, AI-based defect detection, and non-contact inspection methods. As the electronics industry moves toward higher-density, high-performance components, inspection equipment manufacturers are innovating with advanced optical, X-ray, and automated 3D metrology solutions to meet the growing demand for precision and reliability.

Competitive Landscape: Who Are the Key Players?

The global market is highly consolidated, with a limited number of players commanding the majority of market share.

Key Players in the Inspection Equipment Market

Leading companies in the electronics inspection equipment market are investing in AI-driven automation, high-resolution imaging, and nanotechnology-based metrology:

- KLA Corporation – A leader in semiconductor inspection and metrology solutions.

- Nordson Corporation – Specializing in X-ray and automated optical inspection (AOI) systems for PCBs and semiconductors.

- Omron Corporation – Developing AI-powered machine vision and AOI solutions for electronics manufacturing.

- Camtek Ltd. – Focused on high-precision wafer and PCB inspection systems.

- Nikon Metrology – Providing 3D X-ray, CT, and optical inspection solutions for electronics and semiconductor industries.

Key Developments

- April 2024: OMRON Automation Americas introduced the VT-X850, a next-generation 3D CT X-Ray inspection system engineered to meet the stringent quality requirements of electric vehicle (EV) applications and other high-risk assemblies.

- August 2023: JUKI Corporation launched the LX-8 advanced flexible mounter, a versatile system that significantly enhances placement speeds while accommodating a wide range of component sizes through its proprietary Takumi head units.

Key Market Drivers

-

Miniaturization of Electronic Components

The ongoing trend toward miniaturization demands inspection systems capable of handling densely packed, multifunctional products. Traditional inspection methods are becoming obsolete as manufacturers increasingly rely on high-performance solutions—such as AOI, X-Ray inspection, and 3D scanning—to scrutinize minute details like solder joint integrity and component placement accuracy. -

Increasing Demand for Quality Assurance

With electronic products integral to critical applications—from healthcare to transportation—the pressure to adhere to rigorous quality standards has intensified. Manufacturers are investing in advanced inspection equipment to minimize defects, improve product reliability, and ensure compliance with global regulatory frameworks. Enhanced inspection systems enable early defect detection, thus preventing product failures and bolstering brand reputation.

Type Segment Gaining Traction

The market segmentation by type includes Automated Optical Inspection (AOI) Machines, X-Ray Inspection Systems, Solder Paste Inspection (SPI) Systems, and others. In 2024, AOI machines held a 48.5% market share and are anticipated to grow at a rate of 3.9% during the forecast period. AOI systems offer a cost-effective and precise method for evaluating printed circuit boards (PCBs), surface-mount devices, and other assemblies, making them indispensable in today’s high-speed manufacturing environments.

Market Snapshot

- Market Size (2024): US$ 1.7 Billion

- Forecast Market Value (2035): US$ 2.7 Billion

- Growth Rate (CAGR 2025-2035): 4.07%

- Forecast Period: 2025-2035

- Historical Data: 2020-2024

- Quantitative Units: US$ Billion for Value & Thousand Units for Volume

For Complete Report Details, Request Sample Copy from Here –

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86460

Regional Outlook

Asia Pacific, and particularly East Asia, dominates the inspection equipment market for the electronics industry. In 2024, the region accounted for 70.6% of the market share and is projected to maintain notable growth with a CAGR of 3.0% throughout the forecast period. Key electronics manufacturing hubs—such as China, Japan, South Korea, and Taiwan—are driving this expansion by continuously investing in advanced quality testing technologies to meet global standards.

Emerging Trends in the Inspection Equipment Market

- AI and Machine Learning for Automated Defect Detection

- Self-learning AI systems are improving defect classification and predictive maintenance.

- AI-powered inspection reduces false positives, improving production efficiency.

- 3D X-ray and Advanced CT Imaging

- Multi-layer PCB inspection, advanced semiconductor packaging, and high-density electronic components benefit from 3D CT scans.

- Edge Computing for Real-Time Quality Control

- Smart factories are integrating edge AI-powered inspection systems for instantaneous defect identification.

- Sustainability and Green Manufacturing Initiatives

- Eco-friendly electronics manufacturing is driving demand for defect-free production, reducing electronic waste.

- Recycling and refurbished electronics industries are adopting AI-powered quality inspection systems.

Market Segmentation: Understanding the Industry

- By Type: Automated Optical Inspection (AOI) Machines, X-Ray Inspection Systems, Solder Paste Inspection (SPI) Systems, Others

- By Product Type: Printed Circuit Boards (PCBs) – Single-Sided, Multi-Layer, Others; Electronic Modules – Power, Communication, Sensor, Microcontroller, Embedded Processing, Others; Sensors and Actuators – Temperature, Motion & Proximity, Optical, Accelerometers & Gyroscopes, Others

- By Application: Smartphones, Laptops, Televisions, Wearables, Home Appliances, Gaming Consoles/Devices, Other Consumer Electronic Applications

- By Regional Coverage: North America, Western Europe, Eastern Europe, East Asia, South Asia, Central and South America, Middle East and Africa

Key Takeaways for Investors and Industry Leaders

- Advanced Inspection Technologies: The integration of AOI, X-Ray, and 3D inspection systems is vital to address the challenges posed by electronic component miniaturization and complex assemblies.

- Quality Assurance Investments: Manufacturers are increasingly investing in high-precision inspection equipment to meet rigorous quality and regulatory standards, thereby minimizing defects and ensuring product reliability.

- Regional Dominance: Asia Pacific remains the powerhouse for electronics manufacturing, with East Asia leading the way in adopting advanced inspection technologies.

- Opportunities for Innovation: The market presents significant opportunities for strategic investments, technological innovations, and expansion through research and development.

Why This Market Matters

The inspection equipment market for the electronics industry is at the heart of ensuring the production of high-quality, reliable electronic devices. As technological advancements and miniaturization continue to shape the industry, the role of sophisticated inspection systems becomes increasingly critical. These solutions not only safeguard product quality and consumer safety but also drive operational efficiency and competitive advantage in a rapidly evolving market.

Stay ahead in the inspection technology revolution! Get real-time updates on market trends, technological innovations, and strategic insights to make informed business decisions.

Future Outlook: Growth Opportunities and Strategic Recommendations

- Expansion of Smart Factory and Industry 4.0 Technologies

- IoT-enabled inspection equipment will drive real-time monitoring, predictive analytics, and process optimization.

- Rising Investments in AI-Powered Inspection and Automated Metrology

- AI-driven automated defect detection will dominate electronics manufacturing by 2035.

- Integration of Robotics in Electronics Inspection

- Cobots (collaborative robots) with integrated vision systems will streamline high-speed quality control in electronic assembly.

Stay ahead with cutting-edge market insights! Contact us for a detailed analysis and strategic recommendations on the future of electronic inspection technologies.

Buy this Premium Research Report: Purchase Now: https://www.transparencymarketresearch.com/checkout.php?rep_id=86460<ype=S

Conclusion: A High-Growth Market Driven by AI and Automation

The Inspection Equipment Market for the Electronics Industry is on a strong growth trajectory, fueled by advancements in AI-driven automation, semiconductor innovation, and rising quality demands. As electronics become more complex and miniaturized, manufacturers must invest in next-generation inspection solutions to maintain high production yields and reliability.

Explore the Latest Research Reports by Transparency Market Research.

- Flexography Printed Electronics Market (Markt für gedruckte Elektronik im Flexodruck) is valued at US$1.9 Billion in 2023, growing at a 10.9% CAGR to reach US$5.9 Billion by 2034.

- Aerial Target Drones Market (Markt für Luftzieldrohnen) is Valued at US$1.1 Billion in 2023, growing at a 9.6% CAGR to reach US$3.0 Billion by 2034.

- Crystal Pullers Market (Markt für Kristallzieher) is valued at US$482.4 Million in 2023, growing at a 4.8% CAGR to reach US$799.9 Million by 2034.

- RF Antennas Market (Markt für HF-Antennen) is valued at US$2.7 Billion in 2023, growing at a 7.99% CAGR to reach US$6.4 Billion by 2034.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

Follow Us: LinkedIn| Twitter| Blog | YouTube

Distribution channels: Business & Economy, Media, Advertising & PR, Science ...

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release